Accurate and reliable weighing scales are indispensable to almost every industry. The type and weighing capacity of scales can make a huge difference when it comes to industrial or commercial applications.

This is why you need to be extra careful when selecting a scale for this purpose. One popular weighing solution in industrial, commercial, and retail sectors is the platform scales.

These scales give you ease of use, durability, and high measurement accuracy in a wide range of applications from healthcare to retail to manufacturing to shipping and logistics.

This blog covers platform scales in detail, highlighting their working, uses, benefits, and more, so keep on reading till the end.

- What is a Platform Scale?

- Functions and Key Features of a Platform Scale

- Principle and Working of Platform Scales

- Types of Platform Scales

- Platform Scales: Uses In Different Industries and Sectors

- Benefits of Using Platform Scales

What is a Platform Scale?

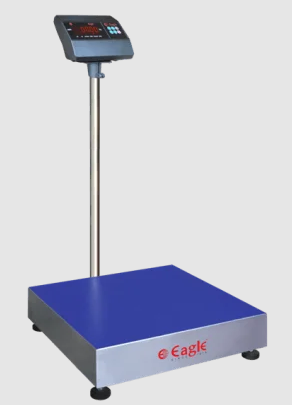

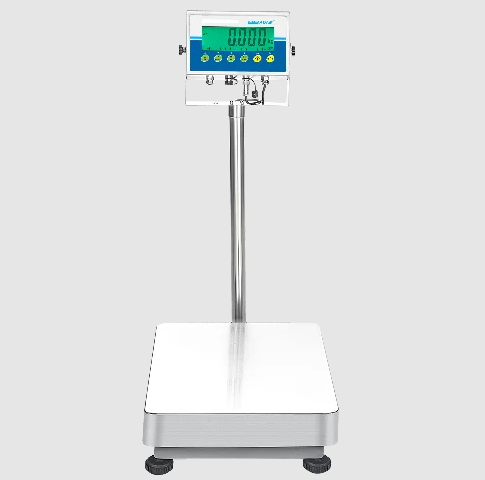

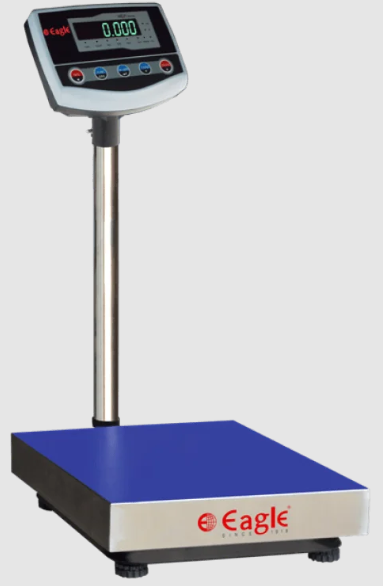

Platform scales are an effective weighing solution for industries that deal with medium to heavy loads. These scales consist of a flat and rugged platform, load cells, and a large digital display.

These scales come in different variations in terms of their sizes, load capacities, and built-in features.

A platform scale gives you greater portability, precision, and productivity, which is why they are used in a wide range of commercial or industrial settings, including manufacturing, pharmaceutical, agriculture, and waste management, to name just a few.

Functions and Key Features of a Platform Scale

There are many unique features and functions that set platform scales apart from regular scales. Here are a few of them to give you just an idea.

- These scales come with flat and stable platforms made from stainless steel that can handle heavy loads with ease.

- Platform scales use high precision and sophisticated sensors to accurately record weight.

- These come with a Tare function that allows you to subtract the weight of the container from the actual weight of the item.

- Platform scales allow you to switch between Kg, g, lb, and other weight units.

- These come with USB ports, WIFI, and Bluetooth features, which facilitate better automation and record-keeping.

- Some models come with an “Alert” feature to ensure overload prevention.

Principle and Working of Platform Scales

Platform scales utilize the principle of conversion of mechanical force into electrical signals. These scales utilize load cells that consist of strain gauge technologies that can detect and convert the applied force or weight of an object into a readable output.

When an object is placed on the platform scale, it applies a force on the load cells. This, in turn, deforms the strain gauges, which leads to a change in their electrical resistance.

The change in resistance is converted into electrical signals with a Wheatstone bridge circuit. The signal is amplified and then sent to the microcontroller, which converts it into a weight reading in your desired units and displays the value on an LCD screen.

Types of Platform Scales

The following are some common types of platform weighing solutions that you normally find being used in different industries.

1. Digital Platform Scale

These are the most widely used platform scales that feature load cells, strain gauges, and digital displays to help you weigh heavy items accurately and instantly.

Most digital platform scales come with batteries, unit conversion, tare, data logging, printing, and WIFI or Bluetooth connectivity features.

These scales are used in warehouses, manufacturing, retail, research, and a wide range of other commercial sectors where you need to maintain high precision and operational efficiency at all times.

2. Analog or Mechanical Platform Scale

A mechanical platform scale, as the name suggests, doesn’t include electronic circuitry or load cells. These scales use a system of interconnected levers, springs, and dials to weigh heavy objects based on counterbalances.

These platform scales are extremely durable, and you don’t need batteries or electricity to operate them. Mechanical platform scales are mostly used in low-tech operations or in locations where electronic systems may fail due to excess heat, moisture, and wear and tear.

3. Floor Scale

Floor scales are designed so that they sit either at or very close to the ground level, which facilitates easier and quicker loading/unloading of objects. These scales feature flat surfaces, ramps, and high-capacity load cells that make them ideal for handling objects that are too large and heavy.

These scales find uses in industrial storage spaces, warehouses, loading bays, and distribution centers.

4. Heavy-Duty Industrial Platform Scale

These scales are designed to weigh very large and heavy objects with high accuracy. These scales feature reinforced platforms and high-capacity load cells. These platform scales also give you anti-slip coatings and conveyor belt integration features, which enhance efficiency and minimize risks.

Shipping, steel plants, large factories, and recycling industries use these scales to ensure reliability and high accuracy.

5. Checkweighing Platform Scale

These are specialized scales that are connected with conveyor belts or production lines. These scales can quickly determine whether a certain item’s weight falls in the predetermined and fixed range or not.

These scales are used in pharmaceutical, food and beverages, and manufacturing sectors to ensure product consistency and regulatory compliance.

6. Counting Platform Scale

Counting scales are commercial scales that can count identical quantities in bulk by dividing the total weight by the average weight of each item placed on the platform.

These scales are extensively used for stocktaking and inventory management. The use of these scales enhances bulk counting accuracy and reduces manual labor and costs significantly.

Platform Scales: Uses In Different Industries and Sectors

The following are some major applications of platform weighing scales in different industries.

- The logistics and Warehousing industry uses these to weigh packages and parcels before and after dispatch to prevent overloading and determine fair freight costs.

- Platform scales are used in the agriculture sector to weigh fertilizers, feed, crops, animals, and inventory.

- These are used in the manufacturing sector to weigh raw materials and finished goods and to ensure quality control.

- Wholesale and Retail industries also use these scales to weigh bulk products and to handle inventory.

- The recycling and Waste Management sector utilizes platform scales to weigh scrap before processing, to ensure accurate billing, and to track environmental regulatory compliance.

- The research and Development sector also uses these for weighing chemicals, reagents, and toxic raw materials.

Benefits of Using Platform Scales

Platform weighing scales are far superior to regular digital weighing machines in terms of their durability, weight capacity, accuracy, and more. The following section lists some amazing benefits of these scales to show you what makes these a suitable option in commercial and industrial settings.

- Greater Accuracy

These scales give you a readability and precision of up to a few grams, which ensures transaction fairness and waste reduction. This also allows businesses to meet regulatory standards and meet customer expectations at all times.

- High Load Capacity

Regular tabletop or smaller scales can handle loads that range from a few grams to a few kilograms. This makes them ineffective in certain industrial use cases.

With platform scales, you can measure the weights of items that weigh several kilograms to tons.

- Ease of Use

Platform weighing scales are very user-friendly. Their easy-to-understand interfaces allow you to take weight readings in different units. Moreover, it is also very easy and safe to load and unload items onto these scales. You can easily place very heavy loads on these scales with forklifts or other common lifting and moving tools.

- Durability

Platform scales are built to withstand harsh industrial conditions. They can handle heavy loads and exposure to water, dust, and chemicals without damage or wear and tear.

These are typically made from industry-grade stainless steel or aluminum, which is responsible for their rugged construction and longer life.

- Versatility

No matter whether you want to weigh large machine parts, small packages, bulky retail items, or a variety of other stuff, you can use platform weighing scales for all these applications.

These scales come in different materials, sizes, and load capacities, and you can easily find one that suits your needs best.

- Data Logging and Integration

Modern platform scales can be integrated with your existing automation, software, or real-time reporting systems. Some versions even come with built-in data logging and report generation features, which give you greater traceability and facilitate better decision-making.

- Reduced Errors and Greater Efficiency

Platform scales allow you to weigh objects before shipping and after delivery, which prevents errors and fosters accountability. These scales provide fast and accurate readings, which prevent fraud and lead to greater overall efficiency in all industrial applications.

Conclusion

Platform scales have revolutionized almost every industry with their greater precision, longer life, ease of use, and versatility. A wide range of industries are utilizing these weighing solutions to enhance efficiency, ensure better quality control, and save time.

These scales come in different types, each offering you useful features like portability, data integration, and digital displays.

Adding platform scales to your operations is a wise investment that can guarantee high ROI in the long run, and that is why you need to consider implementing them in your industry as soon as possible. Visit us at Accurate Meezan today to check out our wide range of highly accurate platform weighing scales and other industrial and personal weighing solutions.